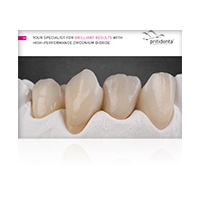

Our products.

Zirconia (ZrO2), glass ceramics, plastics & non-precious metals

This is a combined summary of the wide variety of multicolor and monochrome discs and blocks made of zirconium dioxide, glass ceramics, plastics & non-precious metals. This is complemented by a few useful aids that make your routine tasks easier to complete. We’ve also put together some information about our production process and the pritidenta color chart.

Our mission - Quality "Made in Germany"

pritidenta develops products for dentists and dental technicians which combine highly aesthetic results with efficient manufacture and automation processes in the CAD/CAM sector. Our aim is to offer our customers a cost-effective, high-quality solution. The CAD/CAM materials are manufactured from dental zirconium exclusively in Germany.

Find out more

about our products.

directly as PDF file.

What our customers say about us.

"pritidenta systematized zirconia for success.

Very few of the zirconia blanks on the market stand out as unique. pritidenta found a way with excellent, natural-looking results through CAM techniques. Nesting high or low is not new, of course, but nobody has gone this far to make sure the end results are consistent and predictable..."