![[Translate to English:] priti perfect](/fileadmin/user_upload/product_images/priti_perfect_Finish_01.jpg)

![[Translate to English:] priti perfect](/fileadmin/user_upload/product_images/priti_perfect_Finish_01.jpg)

![[Translate to English:] priti perfect](/fileadmin/user_upload/product_images/priti_perfect_Finish_03.jpg)

![[Translate to English:] priti perfect](/fileadmin/user_upload/product_images/priti_perfect_Finish_04.jpg)

priti®perfect

Stain and Structure paste set

- compact: highly aesthetic and fluorescent pastes, with only 20 components

- effective: 1-firing solution is possible

- controllable: Final colors are already evident during application

You can find ideas for personal finalisation in these videos.

All information about the pastes can be found in this flyer.

Mill your own shade guide! This is how it works:

A shade guide is helpful for shade selection on the patient. Mill the following data sets from zirconia and fire the priti®perfect pastes.

Click here for the data set and the corresponing firing table.

priti®perfect stands for:

Shade stability from model to mouth Control your results perfectly with brush application and ready-to-use paste materials. The final colors are already evident during application.

With only 20 components in the priti®perfect set, it is possible to achieve perfect results in just 1 firing. Depending on the case, the 2 firing solution or internal staining can also be selected.

priti®perfect pink

5 structure pastes and 3 stains for pink esthetics.

APPROVED FOR:

- Zirconium dioxide

- Zirconia layered ceramics

- Metal layered ceramics

- Lithium disilicate

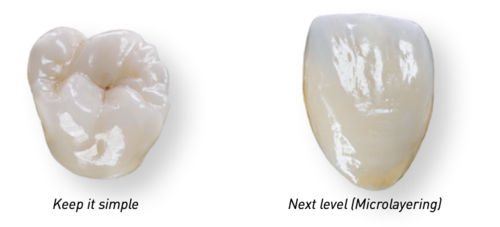

step-by-step to the perfect finish

A - PREPARATION

Condition the surface

- Finish the restoration as usual

- Sandblast

- Clean the surfaces with a steam cleaner

- Apply glaze to whole surface, ensuring there is no pooling

Note: The liquid is only for wetting/cleaning the brush or diluting pastes. It does not create any gloss!

Tip: If liquid has settled in the container, the paste must be stirred thoroughly with a non-metallic instrument.

B - SELECT PROCEDURE.

C - FINISH

Choose from two options:

a) Place the restoration in the furnace immediately. If necessary, finish and polish after firing.

b) When using structural pastes:

4. Keep briefly in ceramic furnace at 300 °C

5. Dry for 10 seconds

6. Finish surface with brush

7. Start firing program

D - FIRING

The temperatures and times given in the table are only for guidance. Each furnace is different, so the parameters need to be adjusted according to the desired level of surface gloss. The rate of temperature rise, the final temperature, and the hold time must be adjusted for larger restorations.

| Firing parameter | Standard | Large | Lithium disilicate |

|---|---|---|---|

| Pre-drying | 3 mins | 10 mins | 3 mins |

| Starting temperature | 450 °C | 450 °C | 450 °C |

| Closing time | 4 mins | 5 mins | 3 mins |

| Temperature rise | 40 °C/min | 30 °C/min | 55 °C/min |

| Vacuum start | 670 °C | 670 °C | 670 °C |

| Final temperature | 775 °C | 775 °C | 720 °C |

| Hold time | 1 min | 1–2,5 min | 1 min |

| Long-term cooling | 3 mins | 10 mins | - |

TinaColoringPlate

Malfarbenplatte für priti®perfect

The TinaColoringPlate comes in a metal box and is designed so that the inlay can be exchanged. It has a black background on the front and a white background on the back. This allows you to work according to your preference. The glass plate is available with one or 31 milled recesses. It sits firmly in the box, but can be removed at any time. This makes it easy to clean.

Our coloring plate can be used universally and can be filled with any color: Link to the Shop

Also interesting for you?

directly as PDF file.