priti®multidisc ZrO2 Multi Translucent

Highest stability

"What makes priti®multidisc ZrO2 Multi Translucent so special?" Following popular demand, this blank combines the positive properties of the already established zirconium dioxide qualities 3Y-TZP and the highly translucent 5Y-TZP in the enamel and in the body.

Maximum safety? A scientific study proves it. Click here for the original report: Link to the study

For all indications

priti®multidisc ZrO2Multi Translucent

Our strong multi-talent can be used for all indications. Highly aesthetic monolithic, full-anatomical crowns, partial crowns and bridges up to 14 units, inlays, onlays, veneers and abutments. Its natural aesthetics and high stability make it suitable for the anterior and visible tooth region. In addition, the cervical opaque zirconium dioxide has good masking qualities. All processing techniques: Staining, cut-back and veneering techniques are possible.

Examples of use

Natural color and translucency gradient + high stability

priti®multidisc ZrO2 Multi Translucent

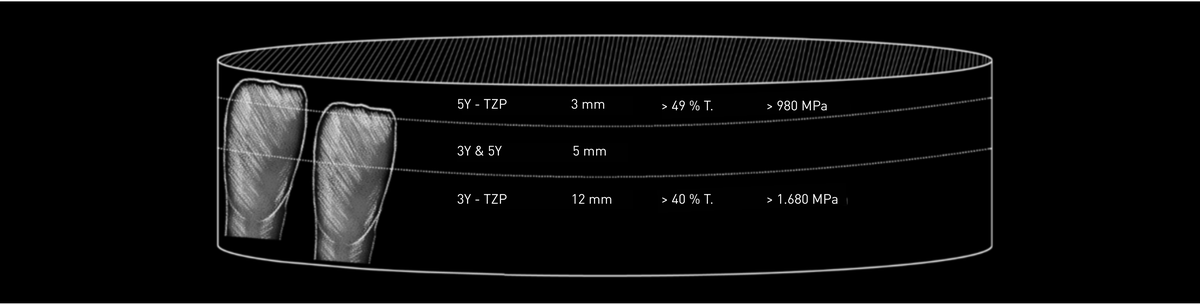

The combination of 3Y-TZP (Translucent with very high strength) and 5Y-TZP (High Translucent with very high translucency) gives a highly aesthetical effect and reliable strength for an unrestricted range of indications. In addition to a smooth transition between the layers within the blank or restoration, this product also has good masking qualities and high stability throughout the blank.

High strength throughout

priti®multidisc ZrO2 Multi Translucent

The smooth transition between the layers results in a gradual progression of strength within the blank or restoration. Multi Translucent is therefore suitable for a wide range of indications.

Material

- Zirconium dioxide Type II, Class 5 according to DIN EN ISO 6872

- Bending strength: typical mean value > 1,440 MPa

- top layer: > 980 MPa

- bottom layer: > 1,680 MPa

- Translucency gradient from > 40% to > 49%

- Thin wall thicknesses of 0.4 mm in the anterior region and 0.6 mm in the posterior region for single crowns

- Precise margins and edges due to highly compressed material

- Veneering is possible with any ceramic material compatible with the CTE 10,5 ± 0,5 ·10-6·K-1 of ZrO₂

- Cross-batch shade fidelity

- Homogeneous staining

- Consistently reproducible shades

- Biocompatible

CHEMICAL COMPOSITION

- Zirconium dioxide (ZrO2/HfO2): 89.89 - 94.65 %

- Yttrium oxide (Y2O3): 4.65 - 10.11 %

- Aluminum oxide (Al2O3): < 0.2 %

- Other oxides: < 0.7 %

Application

The correct use of priti®multidisc ZrO2 Multi Translucent

In order to achieve optimum results and avoid errors, correct application is very important. We have compiled the most important instructions for correct use under the following points.

Variants

Our stable all-rounder

supports you ideally on your individual route to highly esthetic and durable dentures.

Can be used in all indications, available in all 16 VITA classic shades and additionally 3x bleach.

Heights: 16 mm, 20 mm and 25 mm

Blank diameter: 98.5 mm

| Hight | A1 | A2 | A3 | A3,5 | A4 | B1 | B2 | B3 | B4 |

| 16 mm | MZRA1016 | MZRA2016 | MZRA3016 | MZRA3516 | MZRA4016 | MZRB1016 | MZRB2016 | MZRB3016 | MZRB4016 |

| 20 mm | MZRA1020 | MZRA2020 | MZRA3020 | MZRA3520 | MZRA4020 | MZRB1020 | MZRB2020 | MZRB3020 | MZRB4020 |

| 25 mm | MZRA1025 | MZRA2025 | MZRA3025 | MZRA3525 | xxx | xxx | xxx | MZRB3025 | xxx |

| Hight | C1 | C2 | C3 | C4 | D2 | D3 | D4 | OM1 | OM2 | OM3 |

| 16 mm | MZRC1016 | MZRC2016 | MZRC3016 | MZRC4016 | MZRD2016 | MZRD3016 | MZRD4016 | MZROM116 | MZROM216 | MZROM316 |

| 20 mm | MZRC1020 | MZRC2020 | MZRC3020 | MZRC4020 | MZRD2020 | MZRD3020 | MZRD4020 | MZROM120 | MZROM220 | MZROM320 |

| 25 mm | xxx | MZRC2025 | xxx | xxx | xxx | MZRD3025 | xxx | xxx | xxx | xxx |