This is how it works!

Our zirconium dioxide products priti®multidisc ZrO2

Our 6 product variants

with graduated translucencies

- priti®multidisc ZrO2 Multi Translucent PLUS with a translucency of 49 % to 45 %

- priti®multidisc ZrO2 Multi Translucent with a translucency of 49 % to 40 %

- priti®multidisc ZrO2 High Translucent with a translucency of 49 %

- priti®multidisc ZrO2 Extra Translucent with a translucency of 45 %

- priti®multidisc ZrO2 Translucent with a translucency of 40 %

- priti®multidisc ZrO2 Opaque with a translucency of 35 %

Our product series

Multi Translucent, Multilayer and Monochromatic compared

In addition to different levels of translucency, pritidenta® offers variation with three different product series.

Multi Translucent

Multi Translucent is suitable for nearly all areas of application.

In addition to a shade gradient, there is also a translucency gradient. The translucency gradient is possible by combining 3Y-TZP, 4Y-TZP and the highly translucent 5Y-TZP.

Multilayer compact

The efficient solution for a small warehouse with a new color system.

With the new Multilayer product type, we have developed a new shade system and can guarantee perfect shade accuracy for the VITA® Shadeguide as well as an optimum shade gradient with only 8 blanks. In combination with a finalization system (e.g. priti®perfect), perfect results are achieved in every VITA® shade including Bleach.

Monochrome

Proven standard system for frameworks.

Monochrome colored blanks, which are ideal for the fabrication of frameworks and with which great results can be achieved in combination with veneering ceramics.

Suitable for every use

priti®multidisc ZrO2 products for every application

Our sophisticated product portfolio is suitable for many areas of application. This overview helps you to assign the different priti®multidisc ZrO2 products accordingly.

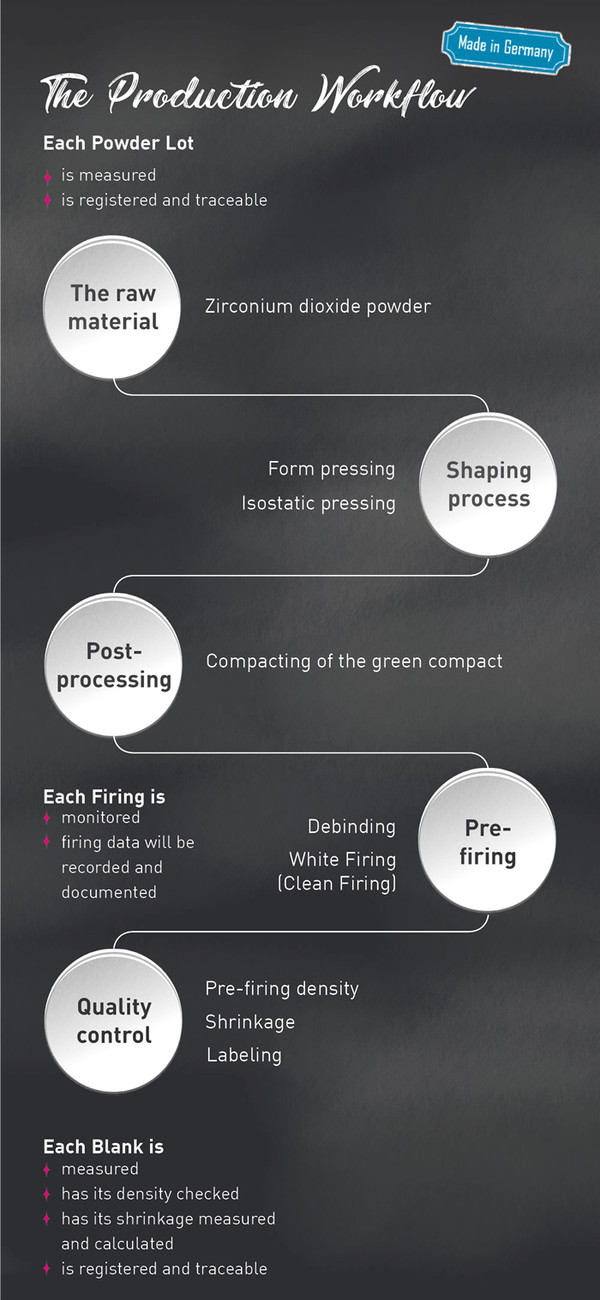

Manufacture

See the production of our zirconium dioxide materials.

priti®multidisc ZrO2 and priti®multibloc ZrO2 blanks are manufactured from formulations developed at our very own production site in the Eifel Region – “made in Germany”. The blanks are produced using a certified process of uniaxial compression followed by cold isostatic pressing. We don’t measure at batch level; each pre-sintered blank is measured individually with sintering shrinkage defined to 4 decimal places.

Download the production workflow as a PDF

Find out more

about our products.

directly as PDF file.

What our customers say about us.

"pritidenta systematized zirconia for success.

Very few of the zirconia blanks on the market stand out as unique. pritidenta found a way with excellent, natural-looking results through CAM techniques. Nesting high or low is not new, of course, but nobody has gone this far to make sure the end results are consistent and predictable..."